Diesel Generator Reliability Standards Ensuring Dependable Power Supply

Introduction

In today's fast-paced world, reliable power supply is crucial for various industries, businesses, and communities. Diesel generators play a significant role in providing backup power during outages or emergencies, ensuring continuity of operations and preventing disruptions. To maintain the highest level of reliability, it is essential for diesel generators to adhere to specific standards and guidelines. This article will delve into the importance of reliability standards for diesel generators, the key factors that influence reliability, and the best practices for ensuring dependable power supply.

Importance of Reliability Standards for Diesel Generators

Reliability standards for diesel generators are essential to ensure that these critical backup power systems perform as expected when needed the most. Whether used in hospitals, data centers, telecommunications facilities, or industrial settings, diesel generators must meet stringent reliability requirements to guarantee uninterrupted power supply during emergencies.

Compliance with reliability standards not only helps prevent costly downtime but also ensures the safety and well-being of individuals who rely on continuous power for life support systems, medical equipment, or critical operations. By adhering to established reliability standards, diesel generator manufacturers can demonstrate the quality and dependability of their products, instilling confidence in end-users and stakeholders.

Key Factors Influencing Reliability of Diesel Generators

Several factors influence the reliability of diesel generators, ranging from design and construction to maintenance and testing practices. Understanding these key factors is essential for enhancing the overall reliability of diesel generators and improving their performance during critical situations. Some of the critical factors that influence the reliability of diesel generators include:

1. Design and Engineering: The design and engineering of a diesel generator play a crucial role in determining its reliability. Factors such as component selection, sizing, configuration, and system integration can impact the overall performance and dependability of the generator. Well-designed generators are more likely to withstand operational stresses and environmental conditions, resulting in higher reliability.

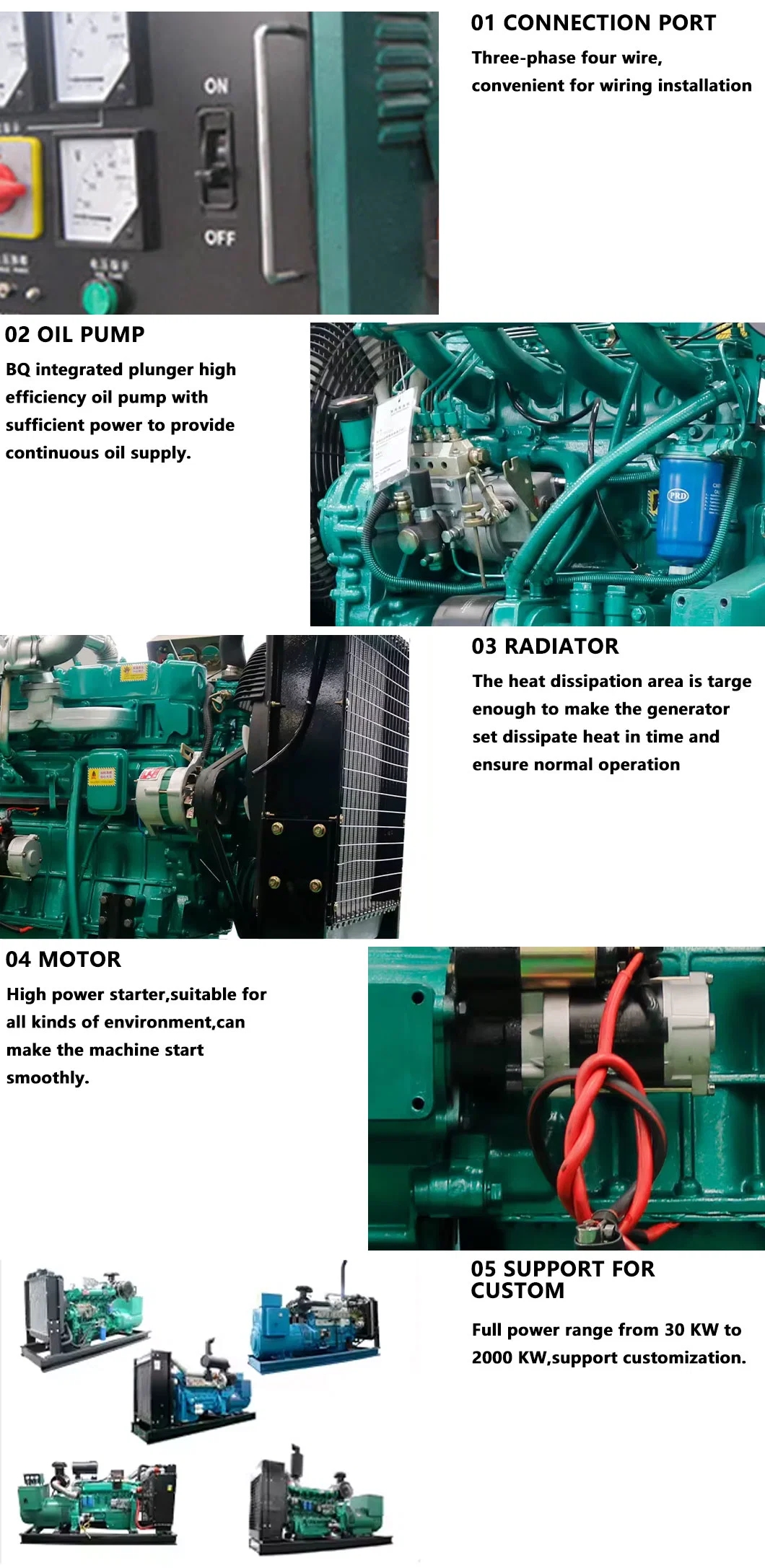

2. Quality of Components: The quality of components used in diesel generators significantly affects their reliability. High-quality engines, alternators, control systems, and other critical parts are less prone to failure and can withstand continuous operation under varying load conditions. Using reliable components from reputable manufacturers can enhance the overall reliability of the generator.

3. Maintenance Practices: Regular maintenance is essential to ensure the reliability of diesel generators. Proper servicing, inspection, and testing help identify potential issues early on and prevent unexpected failures. Adhering to recommended maintenance schedules and using genuine parts and fluids can prolong the life of the generator and maintain its reliability over time.

4. Environmental Conditions: Environmental factors such as temperature, humidity, altitude, and contaminants can impact the performance of diesel generators. 200kw diesel generator for commercial buildings operating in harsh environments or extreme weather conditions may experience higher stress levels, leading to decreased reliability. Adequate protection, ventilation, and monitoring can help mitigate the effects of environmental conditions on generator reliability.

5. Load Profiles: The load profile of a diesel generator, including the type of loads connected and their variation over time, can influence its reliability. Generators subjected to frequent starts, stops, or load changes may experience accelerated wear and tear, affecting their overall performance. Understanding the load profile and sizing the generator appropriately can ensure optimal reliability under varying operating conditions.

Best Practices for Ensuring Dependable Power Supply

To maintain the highest level of reliability for diesel generators, it is essential to follow best practices that encompass design, installation, operation, maintenance, and testing. By implementing these best practices, end-users can optimize the performance of their generators and ensure a dependable power supply when needed. Some of the key best practices for ensuring reliable power supply from diesel generators include:

1. Proper Sizing and Selection: Selecting the right size and type of diesel generator based on the specific power requirements and load profile is crucial for ensuring reliable power supply. Oversized or undersized generators can lead to inefficiencies, increased maintenance costs, and reduced reliability. Consulting with experts and conducting a thorough assessment of power needs can help in proper sizing and selection of the generator.

2. Regular Maintenance and Inspections: Establishing a comprehensive maintenance program that includes regular inspections, servicing, and testing is essential for ensuring the reliability of diesel generators. Following manufacturer's guidelines, conducting routine checks on critical components, and addressing any issues promptly can prolong the lifespan of the generator and prevent unexpected failures.

3. Fuel Quality and Storage: Diesel generators rely on high-quality fuel for optimal performance and reliability. Ensuring the cleanliness, stability, and proper storage of fuel is essential to prevent fuel-related issues such as contamination, degradation, or microbial growth. Regular fuel testing, filtration, and rotation practices can maintain fuel quality and safeguard the reliability of the generator.

4. Load Testing and Monitoring: Conducting regular load tests and monitoring the performance of the diesel generator under varying load conditions is essential for verifying its reliability. Load testing helps identify potential issues, assess the generator's response to different loads, and validate its capacity to handle peak demand. Continuous monitoring of key parameters such as voltage, frequency, and temperature can provide valuable insights into the generator's health and performance.

5. Emergency Preparedness and Response: Developing a comprehensive emergency preparedness plan that outlines procedures for generator startup, shutdown, and troubleshooting can help in ensuring a quick and effective response during power outages or emergencies. Training personnel on emergency protocols, conducting regular drills, and maintaining spare parts and supplies can enhance the reliability of the backup power system and minimize downtime.

Conclusion

In conclusion, diesel generators play a critical role in providing backup power supply during outages or emergencies, ensuring continuity of operations and safeguarding critical systems. To maintain the highest level of reliability, diesel generators must adhere to specific standards and best practices that encompass design, engineering, maintenance, and operation. By following established reliability standards, implementing key best practices, and addressing critical factors that influence reliability, end-users can optimize the performance of their diesel generators and ensure a dependable power supply when needed the most. Reliable power supply is not just a convenience but a necessity in today's interconnected world, and diesel generators continue to be a reliable and trusted source of backup power for various applications and industries.